Space vs Inventory

Written by: Nicole Reps, Sales, Assembly, & Marketing of Flex Craft

When thinking about space on your production floor, workshop, or garage you want to use all available areas to their fullest potential with no wasted space. You might think what’s the best way to store your holiday decorations in your garage or basement? Or what do I have in this work cell that doesn’t need to be here?

Warehouse space is in high demand, and choosing a location for storage is tougher than ever. Maintaining excess inventory will grow more costly, especially for small or mid-sized manufacturers competing for the same finite space as larger companies. Minimizing excess inventory is the only sure way to maintain the margin of products delivered. Leveraging Make-to-Order (MTO) production processing throughout the facility is one way to help lower inventory levels.

Lean manufacturing is built around reducing waste, increasing productivity, and continuously improving processes. Right-sized equipment is a crucial concept of lean manufacturing, focused on minimizing waste, maximizing efficiency, and delivering value to customers. Modifying select machinery to the right size that aligns with the production needs optimizes floor space and enhances overall efficiency. Another core aspect of lean manufacturing is achieving one-piece flow, where products move through the production system one at a time, without delays or bottlenecks. Right-sized equipment ensures that each machine is capable of efficiently processing one piece at a time, minimizing cycle time, and increasing throughput. Visual triggers also help to ensure accurate orders while the production team, supply management, sales, and leadership all work from the same scope and scale.

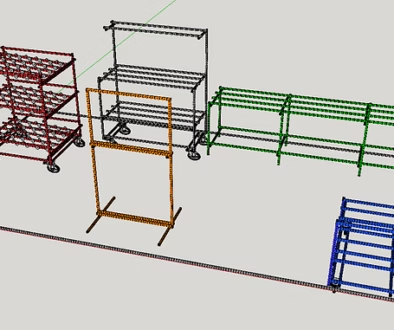

Flex Craft creates custom and efficient workstations by keeping important features such as sizing, motion, and function in mind. You can design workstations to meet the demanding requirements on your specific production floor and help the people who use them perform their designated tasks. Flow Racks help improve efficiency on the work floor by reducing individual movement. Flex Craft racks are specifically designed for you, by you for even the most demanding activities on the assembly floor. Because of Flex Craft’s durability and customization, eliminate the need for temporary flow racks with the options of modifications you make to the assembly floor. For more information on rightsizing structures to your specific work area, don’t hesitate to reach out to the Flex Craft Team today.