Empowering Rapid Continuous Improvement in Lean Manufacturing

Written by: Jake Sparks, Sales, of Flex Craft

In the dynamic world of manufacturing, adaptability and efficiency are paramount. Lean manufacturing principles, such as continuous improvement and waste reduction, are essential for staying competitive. Flex-Craft’s modular framing system offers a versatile solution that aligns seamlessly with these principles, enabling manufacturers to implement changes swiftly and effectively.

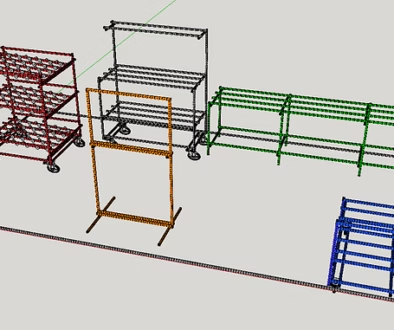

The Flexibility of Modular Design

Flex-Craft’s modular system allows for the quick assembly and reconfiguration of workstations, carts, flow racks, and so much more. This flexibility means that as processes evolve, your equipment can adapt without the need for extensive downtime or costly overhauls. By utilizing standard nuts and bolts, adjustments can be made efficiently, supporting the lean objective of continuous improvement. Best of all as your needs change you simply take apart old structures and turn them into new solutions in minutes.

Supporting Kaizen and 5S Initiatives

Implementing Kaizen—a philosophy of continuous, incremental improvement—is more manageable with tools that support change. Flex-Craft’s system facilitates rapid prototyping and testing of new layouts or processes, encouraging employee involvement and innovation. Additionally, the modular design complements 5S methodologies by promoting organized, clean, and efficient workspaces.

Enhancing Efficiency and Reducing Waste

Lean manufacturing focuses on minimizing waste in all forms. Flex-Craft contributes to this goal by allowing for:

- Quick Reconfiguration: Adapt workstations to new tasks without significant downtime.

- Space Optimization: Design equipment that fits your specific space requirements, reducing unnecessary movement.

- Resource Reuse: Repurpose components for different applications, maximizing the value of your investment.

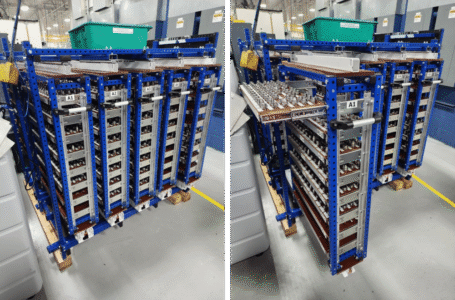

Real-World Applications

Manufacturers across various industries have leveraged Flex-Craft to enhance their lean initiatives. From creating custom assembly lines to developing ergonomic workstations, the modular system has proven to be a valuable asset in driving efficiency and fostering a culture of continuous improvement.

Flex-Craft’s modular framing system is more than just a structural solution—it’s a strategic tool that empowers manufacturers to embrace lean principles fully. By facilitating rapid changes, supporting employee-driven improvements, and reducing waste, Flex-Craft helps organizations stay agile and competitive in an ever-evolving industry landscape.

Contact us today to see why companies ranging from Trane, ABB, HON, Textron, Andersen Windows, and AGCO– to people outfitting their garages use Flex Craft as a tool to make their jobs and lifes so much easier!