Eliminate Waste

Written by: Nicole Reps, Sales, Assembly, & Marketing of Flex Craft

For years, we’ve been told to think outside the box but what if we could redefine “the box”?

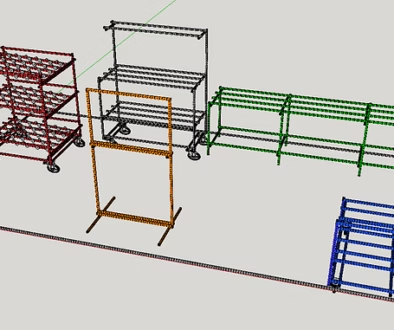

Flex Craft’s material handling system gives you the tools to do just that. With some tubes, nuts, bolts, and imagination, you can take a simple construction technique and build incredible solutions. Since the system is fastened together, your ability to quickly evolve your ideas becomes so much easier. Lean manufacturing isn’t just about carts, workstations, and flow racks, it’s about eliminating waste. What are the wastes (D.O.W.N.T.I.M.E.) and how does Flex Craft help solve those opportunities?

Defects- Eliminate defects by customizing mistake-proofing (poka-yoke) fixtures so all parts must pass through the same setup to advance to the next stage of production.

Overproduction- Limit size and space available on a workstation or cart to only allow discreet quantities of parts. Improve 5S with shadow boards to give each part a place to sit.

Waiting- Our patented rapid-build system creates ideas in minutes to keep production flowing.

Non-Used Employee Talent- From concept to creation, inspire creativity and involve employees in the area to generate buy-in to also improve employee culture.

Transportation- Tugger Carts are excellent options for Automated Guided Vehicle (AGV) systems and distribute assembly parts to various workstations in one trip.

Inventory- Diversity is required, one size doesn’t fit all. Create a flow rack to fit any size box for any future changes.

Motion- Compact controlled and yet easily adjusted workstations and carts. Combination Point of Use Carts to keep things flowing.

Excessive (Over) Processing- Create and combine stations to reduce multiple touches. One-stop information station to include everything from production output to safety.

A picture can be worth a thousand words.

A single idea implemented can lead to so many more evolutionary improvements.