How to Optimize Product Design for Maximum Efficiency

Written by: Nicole Reps, Sales, Assembly, & Marketing of Flex Craft

Efficient product design is the cornerstone of success for businesses across industries. By creating products that balance functionality, cost-effectiveness, and sustainability, companies can boost profitability and customer satisfaction. Let’s explore key strategies to optimize product design for maximum efficiency and see how Flex-Craft solutions can make a difference.

It is vital to fully understand Customer Needs and to deeply understand the pain points and requirements of your target audience. Imagine having detailed insights from customer surveys, market research, or focus groups—this can pave the way to meeting expectations right from the start and avoiding costly redesigns later. Flex-Craft offers custom solutions designed to match your exact specifications. We collaborate closely with you to ensure your product aligns perfectly with customer priorities.

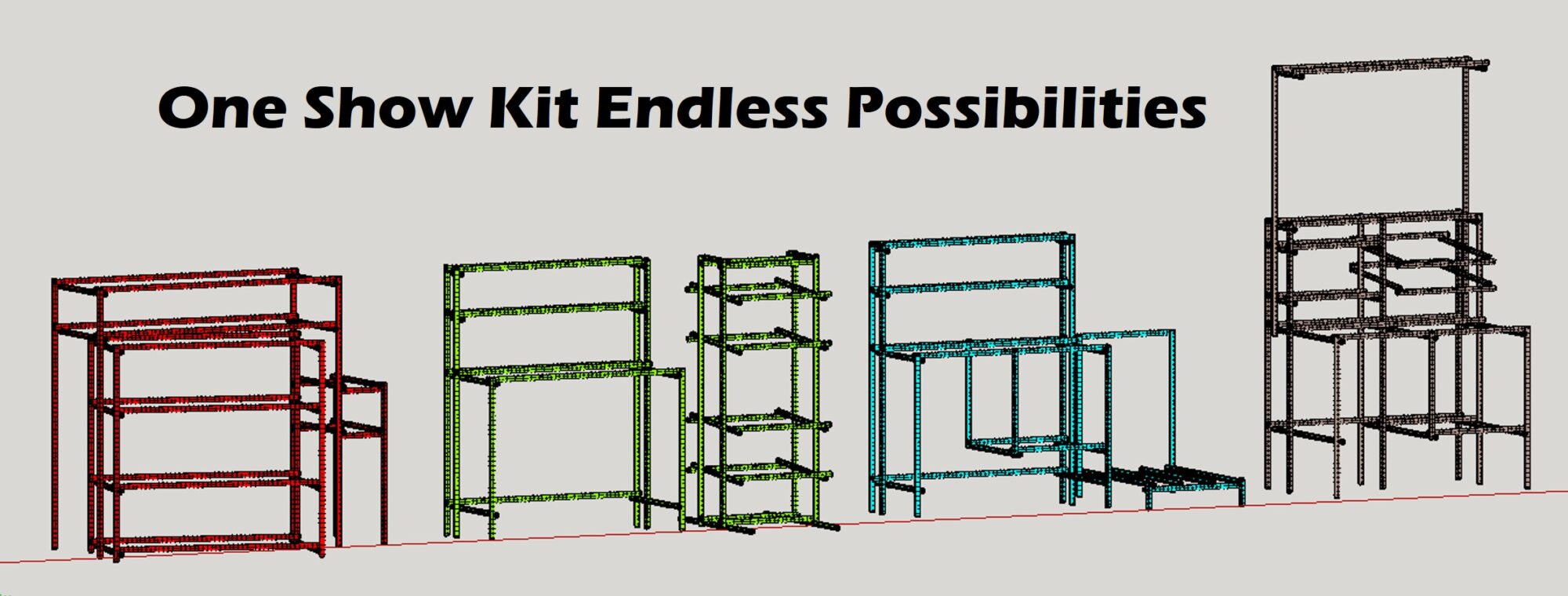

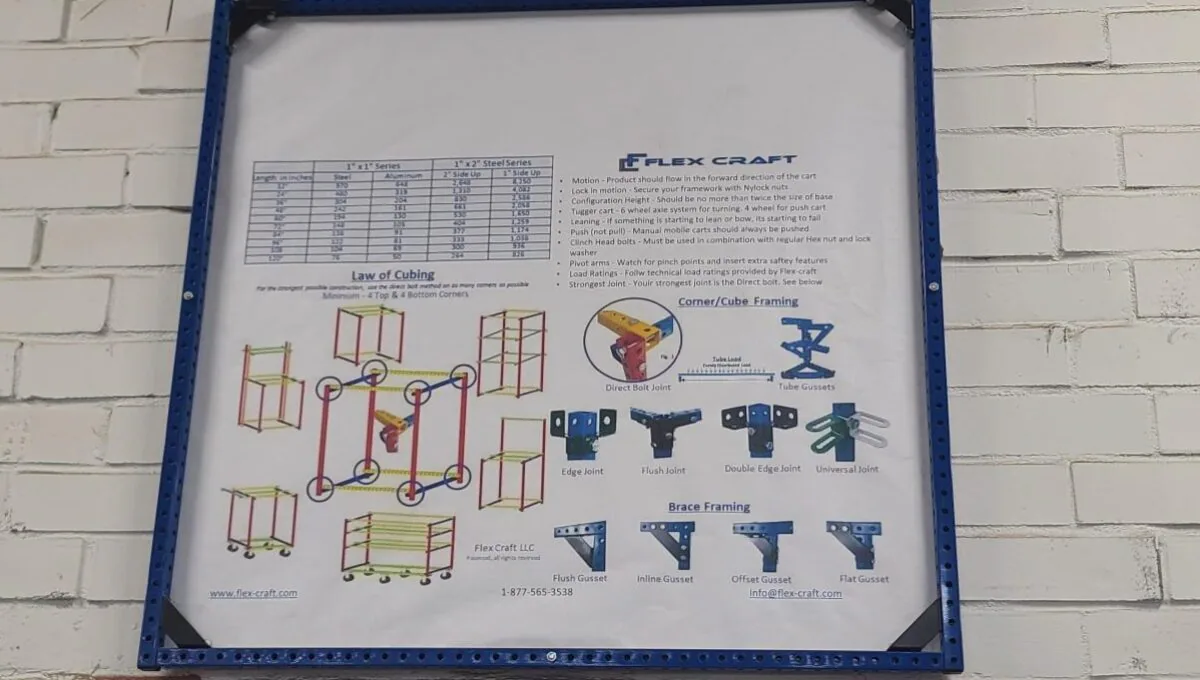

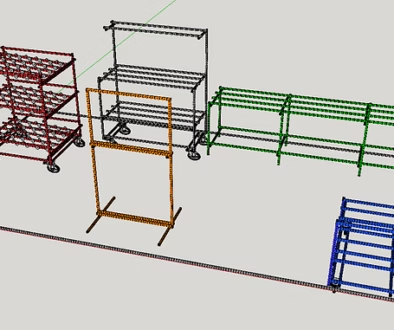

Have you considered the power of modular design? It simplifies manufacturing and maintenance, while also providing flexibility for future upgrades. By creating components that are easy to assemble and replace, you can reduce costs and extend the lifespan of your products. Flex-Craft excels in this area by providing modular and flexible components that integrate seamlessly into your systems. Our customizable tubing and connectors are designed for effortless scalability and reconfiguration, making your processes smoother and more efficient.

In today’s world, sustainability isn’t just a buzzword—it’s a necessity. Think about optimizing material usage, reducing waste, and incorporating recyclable/reusable or biodegradable components. Flex-Craft supports your sustainability goals by offering environmentally friendly materials and using waste-efficient manufacturing processes. This way, you can reduce your carbon footprint and meet the growing demand for greener solutions.

Utilize Advanced Technologies. Imagine having access to cutting-edge tools like CAD software, 3D printing, and simulations that allow you to test designs virtually before committing to production. These technologies enable quick iterations and help you identify inefficiencies early. Flex-Craft employs advanced CAD systems to prototype and refine your designs, and with our rapid prototyping capabilities, you can significantly reduce development cycles and stay ahead of the curve.

Sometimes, simplicity is the key to brilliance. Overengineering can lead to unnecessary complexity and higher costs. By focusing on essential functions, you can streamline your designs to be easier to produce, use, and maintain. Flex-Craft helps by delivering streamlined, high-performance components that eliminate the unnecessary while still ensuring reliability and ease of maintenance.

The best designs often result from collaboration. Bringing together engineering, marketing, and production teams early on ensures that your product is optimized for both functionality and manufacturability. Flex-Craft fosters this collaborative spirit by working alongside your teams to integrate our components seamlessly into your processes. Our customer support is always there to ensure smooth communication and effective problem-solving.

No product is perfect on the first try, which is why testing and iterations are critical. Prototyping and testing in real-world conditions help you identify flaws and refine your design for maximum performance. Flex-Craft offers robust testing support, ensuring our components perform reliably under the most demanding conditions. Plus, our customizable solutions make adjusting during the integration and manufacturing process effortless.

When designing a product, consider its entire lifecycle—from development and production to disposal. This approach ensures your product is efficient not just to build but also to use and maintain. Flex-Craft plays a vital role here with durable components that reduce maintenance costs and extend the lifespan of your products. Moreover, our designs emphasize recyclability. Making it easy to disassemble and the ability to reuse components, making end-of-life processes more cost-effective.

Optimizing product design for maximum efficiency is about finding the right balance of innovation, sustainability, and practicality. With Flex-Craft’s customizable and environmentally conscious solutions, you can create products that deliver exceptional value while staying cost-effective. Let us help you implement these strategies and set your product apart in a competitive market.