Modular Material Handling

What is Modular Material Handling?

To understand Modular Material Handling, first we must understand what makes something “Modular”. By definition, Modular is: “A design approach that subdivides a system/product into smaller parts called modules. A few benefits to modular products are mobility, repurposing, ease of use, and customized flexibility in design.”

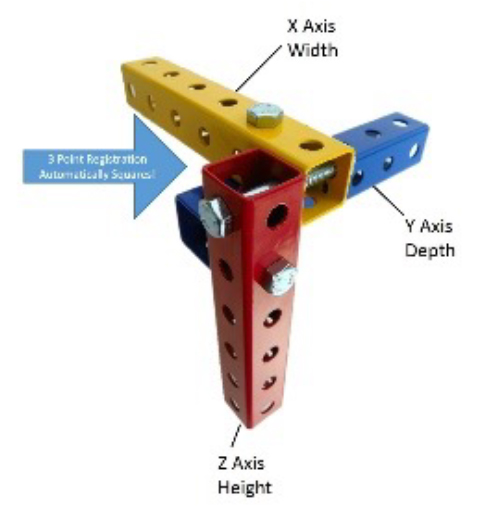

With that said, how can Material Handling products be modular? In the case of Flex Craft, anyone can fully customize their own custom solution by simply utilizing a self-squaring joint with standard nuts and bolts. (See Fig.1). Simply said, if you are building a workstation with shelving underneath the surface, you are able to quickly and easily adjust where the shelves are located by fastening the framing together where it is needed.

Why use Modular Framing Systems?

As Henry Ford once said with regards to innovation: “If I asked people what they wanted, they would have said faster horses”.

In an age were information is only a few swipes of a finger away from prospects, it is critical to keep up and/or stay ahead of consumers desires. We as consumers are rapidly changing our needs, wants, and desires when it comes to the products we consume daily. To keep up with demand, it is critical for manufacturers to be able to change in an instant, while reducing non-value added waste, which will reduce costs, allowing manufacturers to stay competitive and relevant.

Many traditional manufactures are coming out of their caves, actively practicing Lean Manufacturing / Continuous Improvement, doing everything in their power to be ready to adapt to consumer demand.

An easy way to help prepare for the needed changes manufactures face (sometimes on a daily basis) is to utilize Modular Framing Systems. Many Modular Framing Systems such as Flex Craft offer the ability to change at a moment’s notice due to the modular flexibility and additional values that these systems offer. Fig.2 Illustrates how one of Flex Crafts Show Kits can be reconfigured into different solutions.

Modular Benefits & Hidden Value

Nearly every Modular system available can help save manufactures an incredible amount of time and money; however, they all help do this in different ways. Below are ways Flex Craft Products help manufactures in their day-to-day operations and more:

- Modular Benefits

- Try Storming

In a changing environment, it is not always easy to account for everything in a process as these processes often change due to requirements, waste reductions, etc. By utilizing a modular system, you are afforded the luxury of keeping a small inventory on hand to be able to go to Gemba and build quick solutions that may be incomplete initially and add on to them later as needs are further evaluated. - Right Sizing can have a HUGE impact

Whether you are building a table or a cart, space on the shop floor matters and has a premium cost. When using a modular system, it affords you the ability to right size your solutions which can help reclaim more square footage in your operation. It also can help keep areas clean. As in many environments, any flat surface, is an area that something can and will be set on it.

- Try Storming

- Hidden Value

- Quick Return on Investment (ROI)

When utilizing a modular framing system correctly, the ROI can be limitless. Specifically, when you utilize standard size framing (like Flex Crafts offering) the 36” vertical leg of a table today, can be used to create a flow rack tomorrow. This is a huge cost savings compared to traditional “fixed” solutions that are welded together or purchased from catalogs. In most instances, Flex Craft can be used over and over again in different projects. - Employee Empowerment- Creating a sense of Ownership

Specifically, when using Flex Craft, many of our customers have seen an improvement in their day-to-day continuous improvement activities. This empowerment is driven from the fact that operators with just a little bit of training, are able to take Flex Craft Products from pieces and parts to solutions in a matter of minutes. Anyone who can turn a wrench is able to assemble Flex Craft with minimal training and can achieve maximum results!

- Quick Return on Investment (ROI)